工業涂裝流水線的七大組成部分

摘要:噴漆流水線也稱涂裝流水線,指對金屬和非金屬表面覆蓋保護層或裝飾層的專用流水線工具。油漆噴涂主要有干式噴漆室、水簾式噴漆室等,廣泛運用于機械制造、五金家電、電器、燈飾、塑膠件、頭盔、人造石、衛浴、櫥柜門窗、地板、家具、工藝品、醫療器械、汽車零部件、鋁型材、大型裝載機的表面涂裝。

Abstract: Spray painting assembly line, also known as painting assembly line, refers to a specialized assembly line tool for covering protective or decorative layers on metal and non-metal surfaces. Paint spraying mainly includes dry spray painting rooms, water curtain spray painting rooms, etc., widely used in surface coating of machinery manufacturing, hardware and appliances, electrical appliances, lighting fixtures, plastic parts, helmets, artificial stones, bathrooms, cabinet doors and windows, flooring, furniture, handicrafts, medical equipment, automotive parts, aluminum profiles, and large loaders.

涂裝詳解噴漆流水線分懸掛烘干噴漆流水線、平面噴漆流水線、地軌式噴漆烘干流水線三種型式噴漆流水線。1、懸掛噴漆流水線采用懸掛鏈式鏈條輸送、鏈條、軌道可以任意拐彎、升降,主要由噴漆臺、箱體、懸掛輸送系統、加熱系統、控制系統、抽風系統等幾部分組成。箱體框架結構,壁板采用成型烘道板,拆裝方便,保溫效果好。輸送方式采用懸掛鏈條,鏈條根據客戶產品重量可選擇不同型號懸掛鏈條軌道。烘箱加熱方式可采用熱風吹入式或對流式。能源可以是電、柴油、煤、柴、天然氣等。控制系統驅動采用變頻調速馬達,可任意調節速度。溫控采用進口智能型溫控表,控制精度高。并且配有時間表,熱過載等。?2、平面噴漆流水線輸送采用網帶、皮帶、滾筒、輸送工作,主要由噴漆臺、箱體、傳動系統、加熱系統、控制系統、抽風系統等幾部分組成。箱體框架結構,壁板采用成型烘道板,拆裝方便、保溫效果好、輸送方式采用平面網帶、皮帶、滾筒、輸送工作,烘箱加熱方式可采用熱風吹入式或對流式。能源可以是電、柴油、煤、柴、天然氣等。控制系統驅動采用變頻調速馬達,可任意調節速度。溫控采用進口智能型溫控表,控制精度高。3、地軌式噴漆流水線采用地軌鏈條輸送,主要由除塵箱、噴漆臺、箱體、傳動系統、加熱系統、控制系統、抽風系統等幾部分組成。箱體框架結構,壁板采用成型烘道板,拆裝方便,保溫效果好,輸送方式采用地軌鏈條式,地軌鏈條根據客戶方產品重量可選擇不同型號地軌鏈條。烘箱加熱方式可采用熱風吹入式或對流式。能源可以是電、柴油、煤、柴、天然氣等。控制系統驅動采用變頻調速馬達,可任意調節速度。噴漆流水線具有環保、快速干燥、自動控溫、變頻調速、故障報警、操作簡單、外型美觀大方等優點。

The painting assembly line is divided into three types: hanging drying painting assembly line, flat painting assembly line, and ground rail painting drying assembly line. 1. The suspended spray painting assembly line adopts a suspended chain conveyor, and the chain and track can be bent and lifted freely. It mainly consists of a spray painting platform, a box body, a suspended conveyor system, a heating system, a control system, an exhaust system, and other parts. The box frame structure and wall panels are made of molded oven panels, which are easy to disassemble and have good insulation effect. The conveying method adopts a hanging chain, and different types of hanging chain tracks can be selected according to the weight of the customer's product. The heating method of the oven can be hot air blowing or convection. Energy sources can include electricity, diesel, coal, diesel, natural gas, etc. The control system is driven by a variable frequency speed regulating motor, which can adjust the speed arbitrarily. The temperature control adopts imported intelligent temperature control meters with high control accuracy. And equipped with a schedule, thermal overload, etc.? 2. The flat spray painting production line adopts mesh belt, belt, drum, and conveying work, mainly composed of spray painting table, box, transmission system, heating system, control system, exhaust system and other parts. The box frame structure and wall panels are made of molded oven panels, which are easy to disassemble and have good insulation effect. The conveying method adopts flat mesh belts, belts, rollers, and conveying work. The oven heating method can be hot air blowing or convection. Energy sources can include electricity, diesel, coal, diesel, natural gas, etc. The control system is driven by a variable frequency speed regulating motor, which can adjust the speed arbitrarily. The temperature control adopts imported intelligent temperature control meters with high control accuracy. 3. The ground rail spray painting assembly line adopts ground rail chain transportation, mainly composed of dust removal box, spray painting platform, box body, transmission system, heating system, control system, exhaust system and other parts. The box frame structure and wall panels are made of molded oven panels, which are easy to disassemble and have good insulation effect. The conveying method adopts a ground rail chain type, and different models of ground rail chains can be selected according to the weight of the customer's product. The heating method of the oven can be hot air blowing or convection. Energy sources can include electricity, diesel, coal, diesel, natural gas, etc. The control system is driven by a variable frequency speed regulating motor, which can adjust the speed arbitrarily. The spray painting assembly line has the advantages of environmental protection, fast drying, automatic temperature control, variable frequency speed regulation, fault alarm, simple operation, and beautiful appearance.

工程工藝布置1、噴塑線:上輸送鏈——噴塑——烘干(10min、180℃-220℃)——冷卻——下件2、噴漆線:上輸送鏈——靜電除塵——底漆——流平——面漆——流平——烘干(30min、80℃)——冷卻——下件

Engineering Process Layout 1. Spray Coating Line: Upper Conveyor Chain - Spray Coating - Drying (10min, 180 ℃ -220 ℃) - Cooling - Lower Part 2. Spray Coating Line: Upper Conveyor Chain - Electrostatic Dust Removal - Primer - Leveling - Topcoat - Leveling - Drying (30min, 80 ℃) - Cooling - Lower Part

設備組成涂裝流水線的七大組成部分主要包括:前處理設備、噴粉系統、噴漆設備、烘爐、熱源系統、電控系統、懸掛輸送鏈等。

The seven major components of the equipment composition coating assembly line mainly include: pre-treatment equipment, powder coating system, spray painting equipment, oven, heat source system, electrical control system, suspension conveyor chain, etc.

1、前處理設備噴淋式多工位前處理機組是表面處理常用的設備,其原理是利用機械沖刷加速化學反應來完成除油、磷化、水洗等工藝過程。鋼件噴淋式前處理的典型工藝是:預脫脂、脫脂、水洗、水洗、表調、磷化、水洗、水洗、純水洗。前處理還可采用拋丸清理機,適用于結構簡單、銹蝕嚴重、無油或少油的鋼件。且無水質污染。

1. The spray type multi station pre-treatment unit is a commonly used equipment for surface treatment. Its principle is to use mechanical flushing to accelerate chemical reactions to complete processes such as oil removal, phosphating, and water washing. The typical process of spray pre-treatment for steel parts is: pre degreasing, degreasing, water washing, water washing, surface conditioning, phosphating, water washing, water washing, and pure water washing. Pre treatment can also use shot blasting cleaning machines, which are suitable for steel parts with simple structures, severe corrosion, and no or little oil. And there is no water pollution.

2、噴粉系統粉體噴涂中的小旋風+濾芯回收裝置是較先進,換色較快的粉末回收裝置。噴粉系統的關鍵部分建議選用進口產品,噴粉室、電動機械升降機等部件全部國產化。

2. The small cyclone and filter recovery device in powder spraying of the powder spraying system is a relatively advanced and fast powder recovery device with fast color change. It is recommended to use imported products for the key parts of the powder spraying system, and to localize all components such as the powder spraying room and electric mechanical lift.

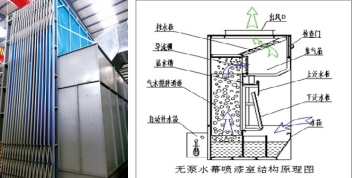

3、噴漆設備如干式噴漆室、水簾式噴漆室等,廣泛運用于機械制造、五金家電、電器、燈飾、塑膠件、大型裝載機的表面涂裝。

3. Spray painting equipment such as dry spray painting rooms and water curtain spray painting rooms are widely used for surface coating in mechanical manufacturing, hardware and household appliances, electrical appliances, lighting fixtures, plastic parts, and large loaders.

4、烘爐烘爐是涂裝生產線中的重要設備之一,它的溫度均勻性是保證涂層質量的重要指標。烘爐的加熱方式有:輻射、熱風循環及輻射+熱風循環等,根據生產綱領可分單室和通過式等,設備形式有直通式和橋式。熱風循環烘爐保溫性好、爐內溫度均勻、熱損失少,經測試,爐內溫差小于±3oC,達到先進國家同類產品的性能指標。

4. Oven drying is one of the important equipment in the coating production line, and its temperature uniformity is an important indicator to ensure the quality of the coating. The heating methods of ovens include radiation, hot air circulation, and radiation+hot air circulation. According to the production schedule, they can be divided into single chamber and through type. The equipment forms include straight through and bridge type. The hot air circulation oven has good insulation, uniform temperature inside the furnace, and low heat loss. After testing, the temperature difference inside the furnace is less than ± 3 ° C, which meets the performance indicators of similar products in advanced countries.

5、熱源系統熱風循環應用較普遍的加熱方式,它利用對流傳導原理對烘爐進行加熱,達到工件的干燥和固化。熱源可根據用戶的具體情況選擇:電、蒸汽、燃氣或燃油等。熱源箱可根據烘爐的情況而定:置于頂部、底部和側部。生產熱源的循環風機如是特制耐高溫風機,則具有壽命長、能耗低、噪聲低、體積小等優點。

5. The hot air circulation application of the heat source system is a common heating method, which uses the principle of convective conduction to heat the oven and achieve the drying and solidification of the workpiece. The heat source can be selected according to the specific situation of the user, such as electricity, steam, gas, or fuel. The heat source box can be determined according to the situation of the oven: placed at the top, bottom, and sides. If the circulating fan for producing heat sources is a specially designed high-temperature resistant fan, it has the advantages of long service life, low energy consumption, low noise, and small size.

6、電控系統涂裝、涂裝流水線電氣控制有集中和單列控制。集中控制能采用可編程序控制器(PLC)來控制主機,根據編制的控制程序對各工序進行自動控制,數據采集和監視報警。單列控制是涂裝生產線中最常用的控制方式,各個工序單列控制,電控箱(柜)設置在設備附近,造價低、操作直觀、維修方便。

6. The electrical control system for painting and painting assembly line has centralized and single row control. Centralized control can use programmable logic controllers (PLCs) to control the host, automatically control each process according to the programmed control program, collect data, and monitor alarms. Single row control is the most commonly used control method in painting production lines. Each process is controlled in a single row, and the electrical control box (cabinet) is located near the equipment, with low cost, intuitive operation, and convenient maintenance.

7、懸掛輸送鏈懸輸機是工業流水線、涂裝線的輸送系統,積放式懸輸機應用于L=10-14M的倉儲貨架和異型路燈合金鋼管涂裝線。工件吊裝在專用掛具上(承重達500-600KG),進出道岔平滑,道岔根據工作指令由電氣控制進行開合,滿足工件在各處理工位的自動輸送,在強冷室、下件區域內平行積放冷卻,并在強冷區域設掛具識別和牽引報警停機裝置。

7. Hanging conveyor chain hanging conveyor is a conveying system for industrial assembly lines and painting lines. The stacking hanging conveyor is applied to L=10-14M storage shelves and special-shaped street lamp alloy steel pipe painting lines. The workpiece is lifted on a dedicated hanging fixture (with a load capacity of 500-600KG), and the entry and exit switches are smooth. The switches are electrically controlled to open and close according to work instructions, meeting the automatic conveying of workpieces at various processing stations. Parallel accumulation cooling is carried out in the strong cooling room and the unloading area, and hanging fixture recognition and traction alarm shutdown devices are installed in the strong cooling area.

本文由 工業涂裝流水線 友情奉獻.更多有關的知識請點擊 http://m.9qmv.com/ 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the industrial painting assembly line For more related knowledge, please click http://m.9qmv.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

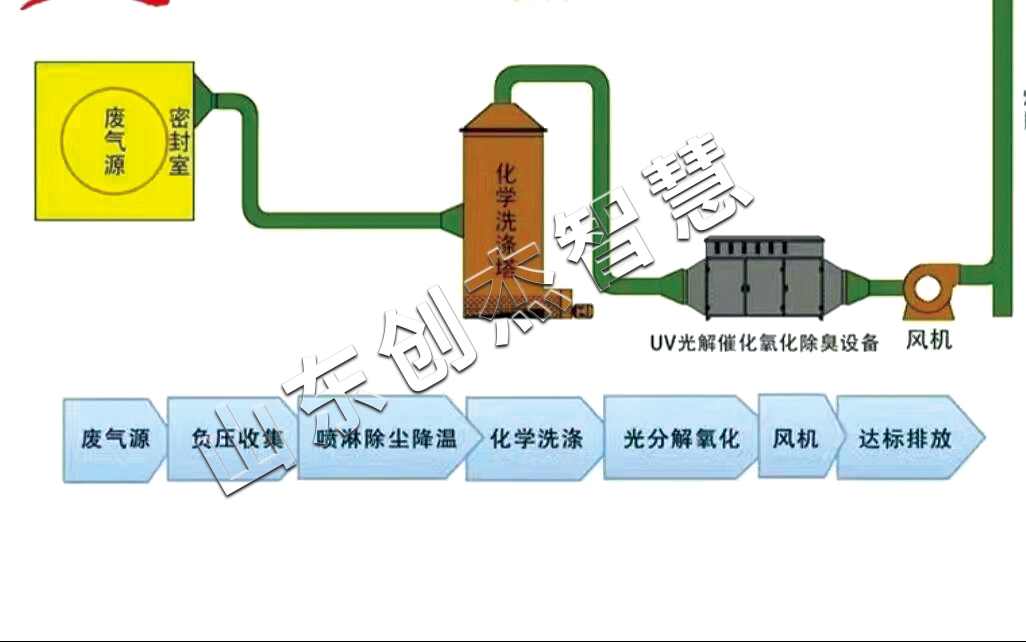

上一篇:VOC廢氣處理工藝詳解

下一篇:涂裝生產線常見問題及解決辦法

魯公網安備 37142502000144號

魯公網安備 37142502000144號