了解自動式拋丸機:從實際應用看其優勢特點

一、在實際工業生產中,自動式拋丸機通過自動化輸送系統實現工件的連續處理,無需人工頻繁搬運工件。工作時,拋丸器將 0.1~1.5mm 的彈丸高速拋向工件表面,經過處理的工件表面會形成合適的粗糙度,不僅讓外觀更整潔美觀,還能通過改變表面壓應力增強工件的耐用性,延長其在后續使用中的壽命。

1、 In actual industrial production, automatic shot blasting machines achieve continuous processing of workpieces through automated conveying systems, without the need for frequent manual handling of workpieces. During operation, the shot blasting machine rapidly throws 0.1-1.5mm pellets onto the surface of the workpiece. The treated surface of the workpiece forms a suitable roughness, which not only makes the appearance cleaner and more beautiful, but also enhances the durability of the workpiece by changing the surface compressive stress, extending its service life in subsequent use.

從應用場景來看,設備在齒輪加工廠里,能快速清理齒輪表面的氧化皮;在鑄造車間,可高效去除鑄件上的毛刺和殘砂;在建筑構件生產中,對鋼材表面進行強化處理,提升其抗腐蝕能力。無論是中小型鑄鍛件,還是細長的軸類零件、薄壁的殼體零件,只要不宜碰撞,它都能穩妥處理。

From the perspective of application scenarios, the equipment can quickly clean the oxide scale on the surface of gears in gear processing plants; In the casting workshop, burrs and residual sand on castings can be efficiently removed; In the production of building components, steel surfaces are strengthened to enhance their corrosion resistance. Whether it is small and medium-sized castings and forgings, slender shaft parts, or thin-walled shell parts, as long as they are not suitable for collision, they can be handled safely.

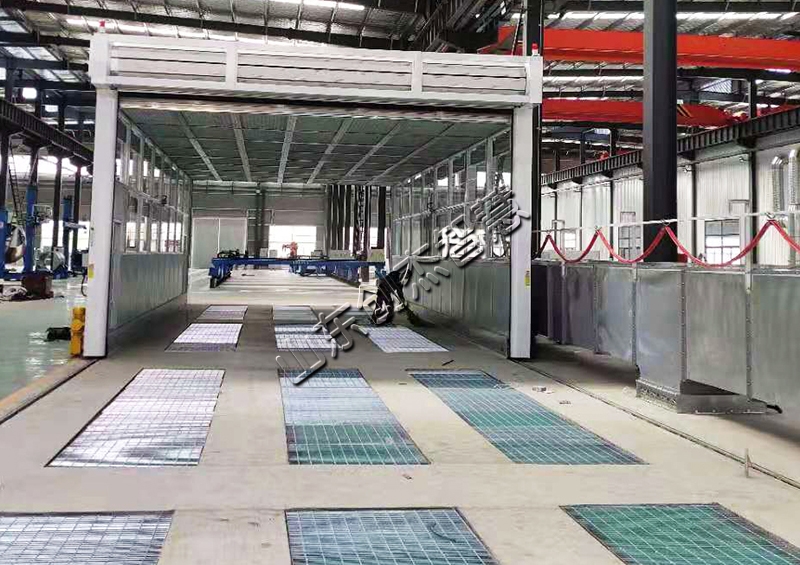

實際操作中,拋丸室的尺寸可根據工廠常加工工件的大小靈活選擇,多個拋頭配合工作,能同時處理多件工件,承載量完全能滿足批量生產的需求。工人只需將工件整齊擺放在輸送帶上,按下啟動按鈕,設備就會自動完成拋丸、清理粉塵和殘余丸料的全過程,整個流程通常 5-7 分鐘就能完成,大大節省了人工成本,提高了生產節奏。

In practical operation, the size of the shot blasting chamber can be flexibly selected according to the size of the workpieces commonly processed by the factory. Multiple polishing heads work together to process multiple workpieces simultaneously, and the load-bearing capacity can fully meet the needs of mass production. Workers only need to neatly place the workpieces on the conveyor belt, press the start button, and the equipment will automatically complete the entire process of shot blasting, cleaning dust and residual shot materials. The entire process usually takes 5-7 minutes to complete, greatly saving labor costs and improving production pace.

二、自動式拋丸機在實際使用中的特點:

2、 The characteristics of automatic shot blasting machine in practical use:

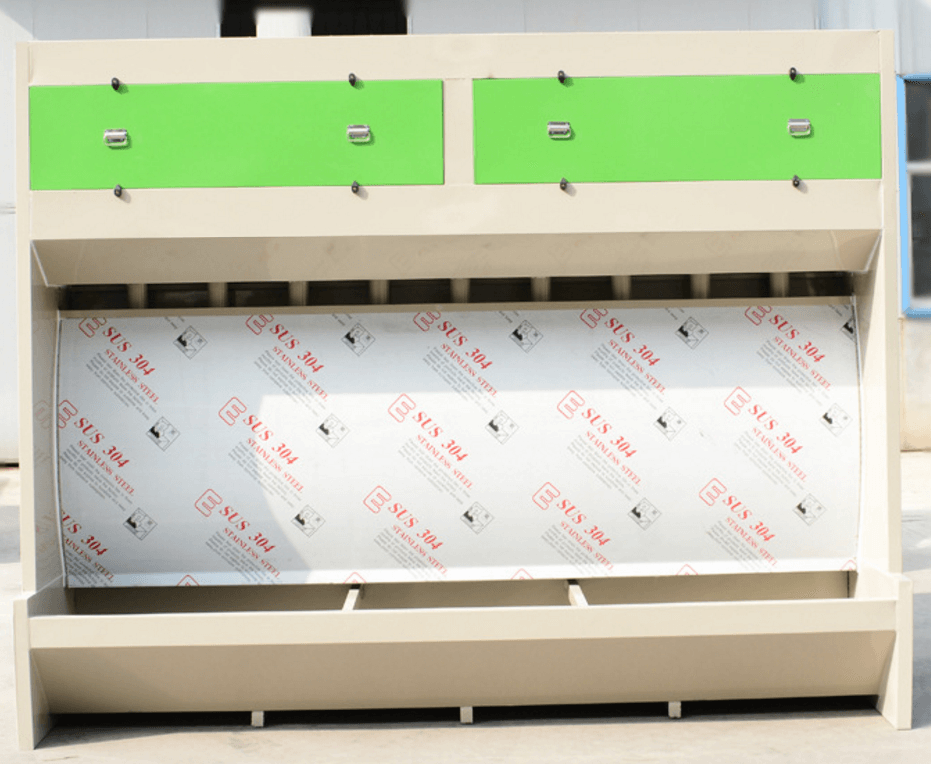

1.機身采用工業級耐用鋼材,能承受長期高強度作業的磨損,機體內側的耐磨護板在經過半年到一年的使用后,若出現局部磨損可單獨更換,不用整體更換,降低了維護成本;

1. The body is made of industrial grade durable steel, which can withstand the wear and tear of long-term high-intensity operations. The wear-resistant protective plate on the inside of the body can be replaced separately if there is local wear after six months to a year of use, without the need for overall replacement, reducing maintenance costs;

2.自動化進出料系統與工廠的生產線銜接順暢,工件從生產線直接進入拋丸機,處理完成后自動送回下一道工序,減少了中間轉運環節,尤其在大批量生產時,效率提升明顯;

2. The automated feeding and unloading system is smoothly connected to the factory's production line. Workpieces are directly fed into the shot blasting machine from the production line, and after processing, they are automatically sent back to the next process, reducing intermediate transportation links. Especially in large-scale production, efficiency is significantly improved;

3.拋丸室的密閉設計在實際使用中能有效避免丸料飛濺到車間地面,保持作業環境整潔,也減少了丸料的浪費;

The sealed design of the shot blasting room can effectively prevent the splashing of shot materials onto the workshop floor in practical use, maintain a clean working environment, and reduce the waste of shot materials;

4.拋丸器的流量控制裝置在處理不同厚度的工件時很實用,比如處理薄鋼板時調小丸料流量,避免工件變形,處理厚鑄件時調大流量,確保清理干凈;

4. The flow control device of the shot blasting machine is very practical when dealing with workpieces of different thicknesses. For example, when dealing with thin steel plates, adjust the flow rate of the shot blasting material to small to avoid workpiece deformation, and when dealing with thick castings, adjust the flow rate to large to ensure cleanliness;

5.鋼丸回收系統在車間連續生產時發揮著重要作用,光電感應裝置會在鋼丸不足時及時報警,提醒工人補充,避免因缺料導致設備空轉影響生產進度;

5. The steel shot recycling system plays an important role in continuous production in the workshop. The photoelectric sensing device will promptly alarm when the steel shot is insufficient, reminding workers to replenish and avoiding equipment idling due to material shortage that affects production progress;

6.分選器能將可回收的鋼丸和雜質徹底分離,分離出的干凈鋼丸可直接再次使用,雜質則被集中收集處理,符合工廠的物料循環利用需求;

6. The sorter can completely separate recyclable steel balls and impurities, and the clean steel balls separated can be directly reused, while impurities are collected and processed centrally, meeting the material recycling needs of the factory;

7.濕式除塵設備在粉塵較多的鑄造車間尤為適用,能有效降低車間粉塵濃度,保障工人的呼吸健康,且日常只需定期換水,維護簡單,不會因頻繁更換備件影響生產;

7. Wet dust removal equipment is particularly suitable in casting workshops with high levels of dust, which can effectively reduce the concentration of dust in the workshop, ensure the respiratory health of workers, and only require regular water changes in daily life. It is easy to maintain and will not affect production due to frequent replacement of spare parts;

8.觸摸顯示屏操作界面對新員工很友好,動畫導引清晰展示了每個操作步驟,即使是剛上崗的工人,經過簡單培訓也能熟練操作,減少了誤操作的可能性;

8. The touch screen operation interface is very friendly to new employees, with clear animation guidance showing each operation step. Even newly employed workers can proficiently operate it after simple training, reducing the possibility of misoperation;

9.設備上的安全提示標簽在車間嘈雜環境中格外醒目,比如 “開機時禁止打開艙門” 的警示,能時刻提醒工人注意安全,維護要點標簽則方便維修人員快速找到需要檢查的部件;

9. The safety warning labels on the equipment are particularly prominent in the noisy environment of the workshop, such as the warning "Do not open the cabin door when turning on", which can always remind workers to pay attention to safety. The maintenance key labels facilitate maintenance personnel to quickly find the parts that need to be inspected;

10.直聯傳動的電機在實際運行中噪音小,不像皮帶傳動那樣容易出現打滑現象,也不用頻繁調整鏈條松緊,減少了設備停機維修的時間,保證了生產線的連續運轉。

10. The direct drive motor has low noise during actual operation, unlike belt drive which is prone to slipping, and does not require frequent adjustment of chain tension, reducing equipment downtime for maintenance and ensuring the continuous operation of the production line.

本文由自動式拋丸機友情奉獻.更多有關的知識請點擊:http://m.9qmv.com我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is dedicated to the automatic shot blasting machine and friendship For more information, please click: http://m.9qmv.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

魯公網安備 37142502000144號

魯公網安備 37142502000144號