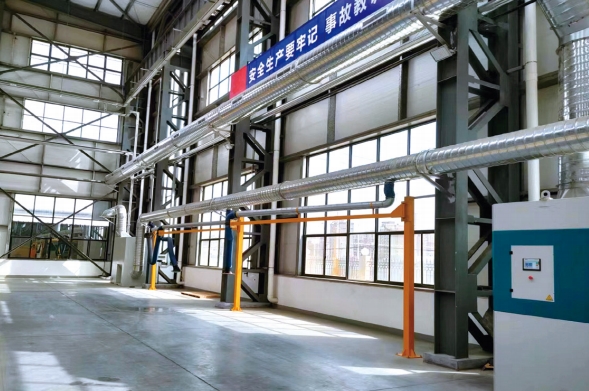

機器人涂裝線廢氣處理工藝

一、機器人涂裝線廢氣簡述:

1、 Brief description of exhaust gas from robot painting line:

在機器人涂裝線過程中產生“三廢”是不可避免的,其中噴涂廢氣是“三廢”的主要部分。機器人涂裝線廢氣來自稀釋劑的揮發,有機溶劑不會隨油漆附著在噴漆物表面,在噴漆和固化過程將全部釋放,形成揮發性有機物(VOCs),主要成分有苯、甲苯及二甲苯等苯系物及其他非甲烷總烴等。噴漆房和晾干室排出廢氣中的VOCs濃度很低,但是風量大,污染物的主要成分為芳香烴、醇醚類及酯類有機物,這種機器人涂裝線產生的VOCs廢氣怎么處理?對此我司昆山鑫藍環保采用沸石轉輪濃縮+催化燃燒。

It is inevitable to generate "three wastes" during the process of robot painting line, among which spraying exhaust gas is the main part of the "three wastes". The exhaust gas from the robot painting line comes from the volatilization of diluents, and organic solvents will not adhere to the surface of the painted material with the paint. They will be completely released during the painting and curing process, forming volatile organic compounds (VOCs), mainly composed of benzene, toluene, xylene and other non methane hydrocarbons. The concentration of VOCs in the exhaust gas emitted from the spray booth and drying room is very low, but the air volume is high. The main components of pollutants are aromatic hydrocarbons, alcohol ethers, and ester organic compounds. How to treat the VOCs exhaust gas generated by this robot painting line? Our Kunshan Xinlan Environmental Protection adopts zeolite wheel concentration and catalytic combustion for this.

二、機器人涂裝線廢氣處理方案:

2、 Waste gas treatment plan for robot painting line:

機器人涂裝線VOC廢氣通過風機輸送至轉輪后,被轉輪上的沸石吸附,從空氣中分離出來。在解吸附區域,所吸附的VOC用一路很小的熱空氣(約180至250℃)吹掃,從沸石上脫附下來,此時VOC濃度被濃縮5至30倍。濃縮后廢氣進入催化燃燒(CO):廢氣中VOCs被濃縮,利用混熱器提供約100℃的小風量熱氣流來進行反吹脫附。脫附出來的高濃度,小風量濃縮廢氣送至催化燃燒設備內催化燃燒分解成CO2和H2O,燃燒放熱回用,節省能源。

The VOC waste gas from the robot painting line is transported to the impeller by a fan and adsorbed by the zeolite on the impeller, which separates it from the air. In the desorption zone, the adsorbed VOCs are blown with a small amount of hot air (about 180 to 250 ℃) to desorb from the zeolite, and the VOC concentration is concentrated by 5 to 30 times. After concentration, the exhaust gas enters catalytic combustion (CO): VOCs in the exhaust gas are concentrated, and a small air flow of about 100 ℃ is provided by a mixer for back blowing desorption. The high concentration and low air volume concentrated exhaust gas desorbed is sent to the catalytic combustion equipment for catalytic combustion and decomposition into CO2 and H2O, which release heat for reuse and save energy.

三、機器人涂裝線廢氣處理設備特點:

3、 Characteristics of exhaust gas treatment equipment for robot painting line:

1.CO催化燃燒設備采用優質金屬鈀,鍍鉑在蜂窩陶瓷載體上作為催化劑,純利效率高達95%-99%,壽命長,可再生,氣體流量大,阻力小。

1. The CO catalytic combustion equipment uses high-quality palladium metal and platinum plated on a honeycomb ceramic carrier as a catalyst, with a pure profit efficiency of up to 95% -99%, long lifespan, renewability, high gas flow rate, and low resistance.

2.安全設施齊全:消防噴淋、泄壓孔、超溫報警等保護設施。

2. Complete safety facilities: protective facilities such as fire sprinklers, pressure relief holes, and over temperature alarms.

3.功耗:預熱15-35分鐘全功率加熱,工作時只消耗風機功率即可。當廢氣濃度低時,自動間歇補償加熱。

3. Power consumption: Preheat for 15-35 minutes for full power heating, and only consume fan power during operation. When the concentration of exhaust gas is low, automatic intermittent compensation heating is used.

4.余熱利用:余熱可返回干燥路徑進行干燥,減少原干燥路徑的功率消耗。

4. Waste heat utilization: Waste heat can be returned to the drying path for drying, reducing the power consumption of the original drying path.

魯公網安備 37142502000144號

魯公網安備 37142502000144號