電泳線適用的工件以及工藝流程,看完這篇就了解!

電泳涂裝作為一種高效、環(huán)保的涂裝技術(shù),在現(xiàn)代工業(yè)中得到了廣泛應(yīng)用。本文將詳細(xì)介紹電泳線適用的工件類型及其工藝流程,幫助讀者更好地理解這一技術(shù)。

Electrophoretic coating, as an efficient and environmentally friendly coating technology, has been widely used in modern industry. This article will provide a detailed introduction to the types of workpieces suitable for electrophoresis lines and their process flow, helping readers better understand this technology.

一、電泳線適用的工件

1、 Workpieces suitable for electrophoresis lines

電泳線適用于多種材質(zhì)的工件,特別是那些對防腐性、裝飾性和均勻性要求較高的產(chǎn)品。以下是一些典型的適用工件類型:

Electrophoretic lines are suitable for workpieces made of various materials, especially for products that require high anti-corrosion, decorative, and uniformity requirements. Here are some typical types of applicable workpieces:

1.金屬工件:如汽車車身、汽車零部件(如輪轂、發(fā)動機(jī)部件)、家電外殼(如冰箱、洗衣機(jī))、建筑五金(如門窗、欄桿)等。金屬工件因其導(dǎo)電性好,非常適合電泳涂裝。

1. Metal workpieces: such as car bodies, car parts (such as wheels, engine components), home appliance casings (such as refrigerators, washing machines), building hardware (such as doors, windows, railings), etc. Metal workpieces are very suitable for electrophoretic coating due to their good conductivity.

2.塑料制品:經(jīng)過特殊處理的導(dǎo)電塑料也適用于電泳涂裝。這類涂料能夠賦予塑料表面金屬質(zhì)感,同時(shí)提高其耐磨、耐腐蝕性能。

2. Plastic products: Specially treated conductive plastics are also suitable for electrophoretic coating. This type of coating can give plastic surfaces a metallic texture while improving their wear and corrosion resistance.

3.玻璃及陶瓷制品:雖然這些材料本身不導(dǎo)電,但可以通過在表面涂覆導(dǎo)電層后進(jìn)行電泳涂裝,以達(dá)到裝飾和防護(hù)的目的。

3. Glass and ceramic products: Although these materials themselves are non-conductive, they can be decorated and protected by electrophoretic coating after coating a conductive layer on the surface.

4.其他導(dǎo)電基材:如導(dǎo)電纖維、導(dǎo)電薄膜等,在特定應(yīng)用場合下也需進(jìn)行電泳涂裝處理。

4. Other conductive substrates, such as conductive fibers, conductive films, etc., also require electrophoretic coating treatment in specific application scenarios.

二、電泳涂裝工藝流程

2、 Electrophoretic coating process flow

1.預(yù)處理:

1. Preprocessing:

(1)預(yù)清理:清除工件表面的大顆粒雜質(zhì)和油污。

(1) Pre cleaning: Remove large particle impurities and oil stains from the surface of the workpiece.

(2)除油:通過化學(xué)或物理方法去除工件表面的油脂和污垢,確保表面清潔。

(2) Oil removal: Remove grease and dirt from the surface of the workpiece through chemical or physical methods to ensure surface cleanliness.

(3)除銹:針對金屬工件,采用噴砂、酸洗等方法去除表面銹蝕,提高附著力。

(3) Rust removal: For metal workpieces, methods such as sandblasting and acid washing are used to remove surface rust and improve adhesion.

(4)磷化:在工件表面形成一層磷化膜,提高涂層的附著力和耐腐蝕性能。

(4) Phosphating: Form a layer of phosphating film on the surface of the workpiece to improve the adhesion and corrosion resistance of the coating.

(5)水洗:多次水洗以去除前處理過程中殘留的化學(xué)物質(zhì),保證表面清潔。

(5) Water washing: Multiple water washes to remove residual chemicals from the pre-treatment process and ensure surface cleanliness.

2.電泳涂裝:

2. Electrophoretic coating:

(1)將預(yù)處理后的工件浸入電泳槽中,作為陽極(陽極電泳)或陰極(陰極電泳)。

(1) Immerse the preprocessed workpiece into an electrophoresis tank as an anode (anodic electrophoresis) or cathode (cathodic electrophoresis).

(2)在電泳槽中,涂料(電泳漆)與水按一定比例稀釋后,形成帶電膠體粒子。

(2) In the electrophoresis tank, the coating (electrophoretic paint) is diluted with water in a certain proportion to form charged colloidal particles.

(3)在直流電場的作用下,帶電膠體粒子向工件表面移動并沉積,形成均勻的涂層。

(3) Under the action of a direct current electric field, charged colloidal particles move and deposit onto the surface of the workpiece, forming a uniform coating.

3.電泳后清洗:

3. Cleaning after electrophoresis:

(1)取出工件后,用超濾液和去離子水進(jìn)行多次清洗,以去除表面殘留的涂料和其他雜質(zhì)。

(1) After removing the workpiece, clean it multiple times with ultrafiltrate and deionized water to remove residual coating and other impurities on the surface.

(2)清洗過程中注意避免涂層被破壞或產(chǎn)生二次流痕等弊病。

(2) During the cleaning process, be careful to avoid coating damage or secondary flow marks.

4.烘干成膜:

4. Drying to form a film:

(1)將清洗后的工件送入烘爐中,在規(guī)定的溫度和時(shí)間下烘干,使涂層完全固化。

(1) Send the cleaned workpiece into an oven and dry it at the specified temperature and time to fully cure the coating.

(2)烘干過程中需注意溫度均勻性,以保證涂層質(zhì)量。

(2) During the drying process, attention should be paid to temperature uniformity to ensure the quality of the coating.

5.冷卻與后處理:

5. Cooling and post-processing:

(1)烘干后的工件進(jìn)行自然冷卻或強(qiáng)制冷卻。

(1) The dried workpiece is subjected to natural cooling or forced cooling.

(2)根據(jù)需要,進(jìn)行后續(xù)的面漆涂裝或其他表面處理工序。

(2) Perform subsequent topcoat coating or other surface treatment processes as needed.

6.特殊工藝與注意事項(xiàng)

6. Special processes and precautions

(1)多孔和縫隙零件:對于這類零件,可在脫脂后增加中途吹水工序,以防縫隙或孔中的水影響后續(xù)工序質(zhì)量。

(1) Porous and crevice parts: For these types of parts, an intermediate water blowing process can be added after degreasing to prevent water in the crevices or holes from affecting the quality of subsequent processes.

(2)特殊材料:如高孔隙的粘接釹鐵硼磁體,可能需要增加有機(jī)封孔工序以提高涂層質(zhì)量。

(2) Special materials, such as high porosity bonded neodymium iron boron magnets, may require additional organic sealing processes to improve coating quality.

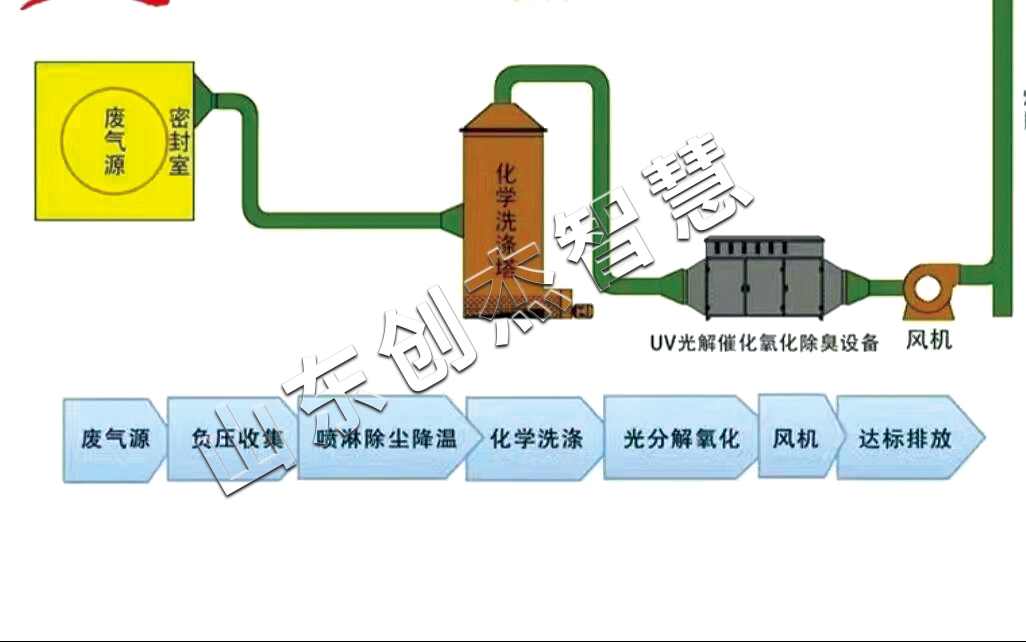

環(huán)保與安全:電泳涂裝過程中會產(chǎn)生廢液和廢氣等污染物,需配置相應(yīng)的三廢處理裝置以確保環(huán)保達(dá)標(biāo)。同時(shí),操作人員需穿戴必要的防護(hù)裝備以確保安全。

Environmental Protection and Safety: During the electrophoretic coating process, pollutants such as waste liquid and exhaust gas are generated, and corresponding three waste treatment devices need to be configured to ensure environmental compliance. At the same time, operators need to wear necessary protective equipment to ensure safety.

電泳線適用于多種材質(zhì)的工件,其工藝流程包括預(yù)處理、電泳涂裝、電泳后清洗、烘干成膜及冷卻與后處理等主要步驟。通過合理的工藝設(shè)計(jì)和嚴(yán)格的操作控制,可以確保獲得高質(zhì)量的電泳涂層產(chǎn)品。

The electrophoresis line is suitable for workpieces made of various materials, and its process includes main steps such as pretreatment, electrophoresis coating, post electrophoresis cleaning, drying to form a film, and cooling and post-treatment. Through reasonable process design and strict operational control, high-quality electrophoretic coating products can be ensured.

本文由 電泳線 友情奉獻(xiàn).更多有關(guān)的知識請點(diǎn)擊 http://m.9qmv.com/ 真誠的態(tài)度.為您提供為全面的服務(wù).更多有關(guān)的知識我們將會陸續(xù)向大家奉獻(xiàn).敬請期待.

This article is a friendly contribution from the electrophoresis line For more related knowledge, please click http://m.9qmv.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

上一篇:VOCs廢氣處理:9大工藝、適用范圍、成本控制

下一篇:伸縮噴漆房的應(yīng)用范圍是什么?解決了客戶的什么難題

魯公網(wǎng)安備 37142502000144號

魯公網(wǎng)安備 37142502000144號