機器人涂裝線的前處理如何做才能提高效率

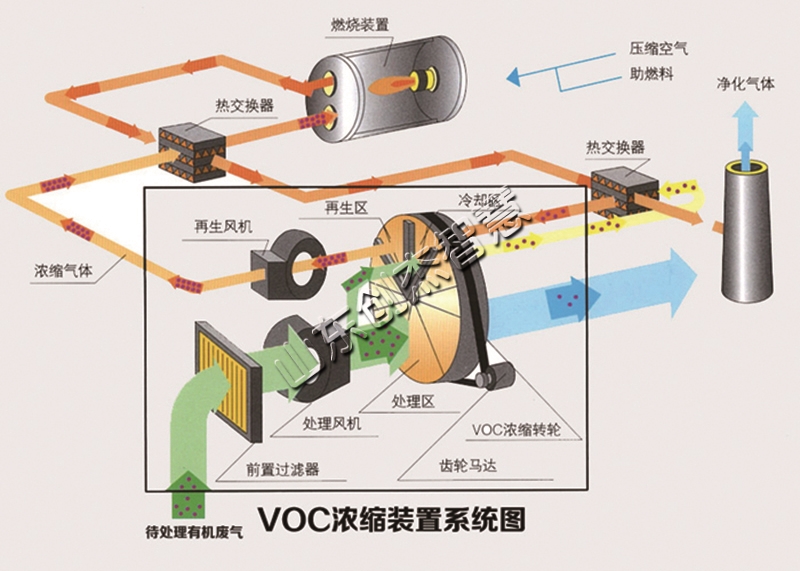

涂裝噴涂線的主要組成部分包括:前處理設備、粉末噴涂系統、噴涂設備、烘烤箱、熱源系統、電控系統、懸掛輸送鏈等。涂裝線的前處理設備是在涂裝前清除涂裝表面的各種油污和灰塵,使涂裝表面清潔的清除工序是涂裝前處理過程中必不可少的。更少的工序,消除了被涂物的基材和表面狀況,涂裝工藝需要選擇。

The main components of the painting and spraying line include pre-treatment equipment, powder spraying system, spraying equipment, oven, heat source system, electrical control system, suspension conveyor chain, etc. The pre-treatment equipment of the painting line is essential for removing various oil stains and dust from the painted surface before painting, and the cleaning process of the painted surface is indispensable in the pre-treatment process of painting. Fewer processes eliminate the substrate and surface condition of the coated material, and the coating process needs to be selected.

在建立涂裝線前處理時,必須先完成工藝設計,然后才能進行非標設備的設計、制造和安裝。因此,工藝設計是建立生產線的基礎,正確合理的路線將對生產操作和產品質量產生良好的影響。

Before establishing the pre-treatment of the painting line, the process design must be completed first, and then the design, manufacturing, and installation of non-standard equipment can be carried out. Therefore, process design is the foundation for establishing a production line, and a correct and reasonable route will have a good impact on production operations and product quality.

前處理的具體分類:前處理是在涂裝前清除工件表面的氧化皮、鐵銹、油脂、灰塵等污垢,使涂裝粉末與金屬表面牢固結合的過程,附著力強,使產品獲得高品質,延長產品使用壽命。

The specific classification of pre-treatment: pre-treatment is the process of removing oxide scale, rust, grease, dust and other dirt from the surface of the workpiece before painting, so that the coating powder can firmly bond with the metal surface, with strong adhesion, resulting in high-quality products and extending product service life.

脫脂----水洗----表面調整----貼膜----水洗(根據工件特性靈活調整)。前處理分為噴淋式、浸泡式、潛泳式三種形式。根據工件和具體的生產要求選擇處理方法。目前噴涂設備管道的表面處理普遍采用噴淋式聯合清洗機。清洗原理是利用噴霧機械力和化學作用完成脫脂、磷化、鈍化、清洗等過程。

Degreasing - Water washing - Surface adjustment - Film coating - Water washing (flexible adjustment according to the characteristics of the workpiece). Pre treatment is divided into three forms: spraying, soaking, and diving. Select the processing method based on the workpiece and specific production requirements. At present, the surface treatment of spraying equipment pipelines generally adopts a spray type combined cleaning machine. The cleaning principle is to use spray mechanical force and chemical action to complete degreasing, phosphating, passivation, cleaning and other processes.

涂裝設備流水線的七大組成部分主要包括:前處理設備、噴粉系統、噴漆設備、烘箱、熱源系統、電控系統、懸掛輸送鏈等。如脫脂、磷化、清洗、干燥、噴粉、固化。這是一個系統的、連貫的過程,是涂裝設備流水線的基本生產特征。

The seven major components of the painting equipment assembly line mainly include: pre-treatment equipment, powder coating system, spray painting equipment, oven, heat source system, electrical control system, suspension conveyor chain, etc. Such as degreasing, phosphating, cleaning, drying, powder coating, and curing. This is a systematic and coherent process, which is the basic production characteristic of the painting equipment assembly line.

“那么有什么方法可以提高噴涂線的效率呢?”

So what methods are available to improve the efficiency of the spraying line

1.提高衣架的利用率

1. Improve the utilization rate of hangers

根據工件的大小和類型,我們可以選擇全套吊具或單室吊具。如果工件不完整,有空閑吊點,我們將整套吊具改為單臺吊具,以提高吊具的有效利用率。如果工件種類多,就需要使用兩用掛架,這樣一個掛架可以掛不同的工件,不用頻繁更換掛架。

According to the size and type of the workpiece, we can choose a complete set of lifting equipment or a single room lifting equipment. If the workpiece is incomplete and there are available lifting points, we will replace the entire set of lifting equipment with a single lifting equipment to improve the effective utilization rate of the lifting equipment. If there are multiple types of workpieces, a dual-purpose hanger is needed, so that one hanger can hang different workpieces without frequent replacement.

2.增加備用油箱

2. Add a backup fuel tank

在生產旺季,涂裝設備流水線也24小時不間斷運行。由于產量的增加,脫脂罐和預脫脂罐中的罐液往往在幾天內就需要更換,更換罐液也占用了正常生產時間的一部分。為了保證產品質量,不耽誤正常生產時間,我們對線體進行了改造。在原有脫脂罐和預脫脂罐的基礎上,并聯了脫脂罐和預脫脂罐。無論何時更換浴液,都不會影響正常生產時間,只需提前準備另一種浴液即可。這也是提高噴涂線生產效率的有效途徑。

During the peak production season, the painting equipment assembly line also operates 24 hours a day without interruption. Due to the increase in production, the tank solution in the degreasing tank and pre degreasing tank often needs to be replaced within a few days, and replacing the tank solution also takes up a part of the normal production time. In order to ensure product quality and not delay normal production time, we have made modifications to the production line. On the basis of the original degreasing tank and pre degreasing tank, degreasing tank and pre degreasing tank are connected in parallel. No matter when the bath is changed, it will not affect the normal production time, just prepare another type of bath in advance. This is also an effective way to improve the production efficiency of the spraying line.

3、精細化管理

3. Refined management

通過精細化管理,可以掌握各工序的實際產能,為合理組織生產和平衡產能提供基礎數據支持,關注涂裝工藝,細化各工序的操作步驟、工藝參數、操作規范等。每個過程。在工藝文件中,任何工人都可以按照工藝文件的規定生產出合格的產品。統籌協調整條涂裝線的產能。

Through refined management, the actual production capacity of each process can be grasped, providing basic data support for rational organization of production and balancing production capacity. Attention should be paid to the coating process, and the operational steps, process parameters, and operating specifications of each process can be refined. Each process. In the process document, any worker can produce qualified products according to the regulations of the process document. Coordinate the production capacity of the entire painting line.

四、新漆前處理的使用

4、 The use of pre-treatment for new paint

在實際生產中,積極使用新型預處理劑,提高生產效率。過去,使用傳統的油漆前處理劑,溫度要求在50℃以上,每班生產前,都需要漫長的加熱過程,尤其是在寒冷的冬季,有時達不到設定溫度很長時間。后來又采用了新型低溫磷化劑和脫脂劑,大大縮短了加熱過程。方便生產管理,增加有效工作時間,從而提高生產效率。不僅如此,還能節約生產成本,實現多重目標。

In actual production, actively using new pretreatment agents to improve production efficiency. In the past, using traditional paint pre-treatment agents required a temperature of over 50 ℃, and a long heating process was required before each shift of production, especially in the cold winter when the set temperature could not be reached for a long time. Later, new low-temperature phosphating agents and degreasing agents were used, greatly shortening the heating process. Facilitating production management, increasing effective working time, and thus improving production efficiency. Not only that, but it can also save production costs and achieve multiple goals.

涂裝設備、工作環境、涂裝管理、涂裝工藝和材料直接關系到噴涂線的生產效率。在這個過程中,涂裝設備的工藝布置對噴涂線的使用有著重要的影響。因此,精益涂裝的裝配工藝也是有效提高其效率的重要因素之一。

The painting equipment, working environment, painting management, painting process, and materials are directly related to the production efficiency of the spraying line. In this process, the process layout of the painting equipment has a significant impact on the use of the spraying line. Therefore, the assembly process of lean coating is also an important factor in effectively improving its efficiency.

本文由 機器人涂裝線 友情奉獻.更多有關的知識請點擊 http://m.9qmv.com/ 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the robot painting line For more related knowledge, please click http://m.9qmv.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

上一篇:車間整體除塵設備:智能鋼構車間焊煙除塵方案助力企業解決煙塵難題

下一篇:工業涂裝流水線:如何解決軌道車輛涂裝線中生產效率和產品質量的矛盾?

魯公網安備 37142502000144號

魯公網安備 37142502000144號